Trial of Zero-waste Ecosystem Solution

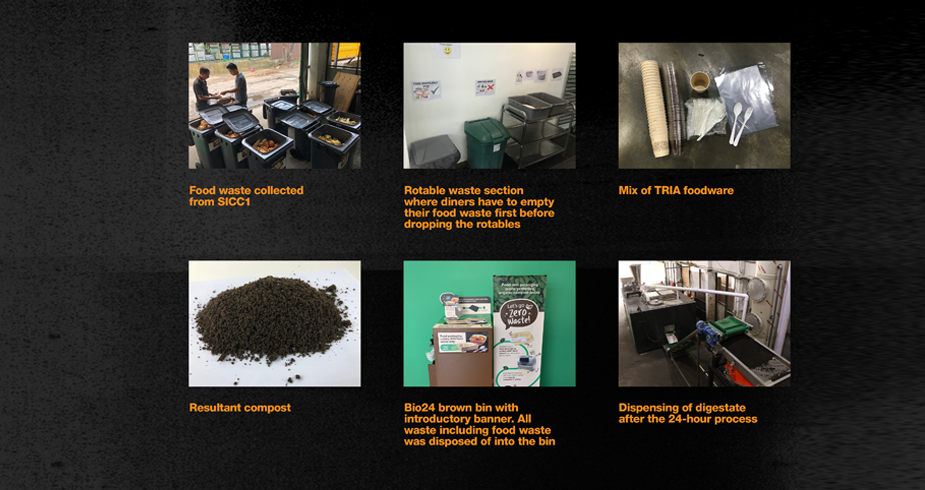

In November 2019, SATS partnered the Singapore Institute of Technology (SIT) to conduct a three-week trial programme at one of SIT’s campus canteens, iEat Café, which turns food and food packaging waste into fertiliser.

Developed by TRIA, a Singapore based company that develops sustainable food packaging, the Bio24 programme (https://triabio24.com) is a zero-waste ecosystem solution that turns single-use foodware, packaging, and food waste into farm-ready fertiliser. By replacing the plastics used in single-use foodware with a plant-based material called NEUTRIA, foodservice waste can be streamlined into a single organic waste stream.

This can then be digested by TRIA’s patented biodigester, which turns the waste into fertiliser within 24 hours.

The main objective of the trial was to better understand the digestibility of food and packaging waste materials as well as the viability of operational adoption. In addition to iEat Café’s operations, about 600 kg of food waste was collected from SATS Inflight Catering Centre (SICC) 1 and successfully digested into compost in order to test the quality of the resultant digestate. By the end of the trial period, iEat Café managed to achieve zero waste on 91.5% of their foodservice by-products by turning food and packaging waste into nutrient-rich compost.

Our zero-waste ecosystem solution.

Advocating sustainable behaviour among our employees

Sustainability is a holistic approach that determines the way we operate as a business and the choices we make as individuals. To build a corporate culture that promotes sustainability through behavioural change, we regularly communicate our sustainability pillars to our employees through many different platforms to encourage the rethinking of individual consumption patterns in our daily lives.

To promote this shift in mindset and serve as a source of inspiration, SATS has started an initiative to feature ‘sustainability champions’, individuals who display sustainable and responsible behaviour.

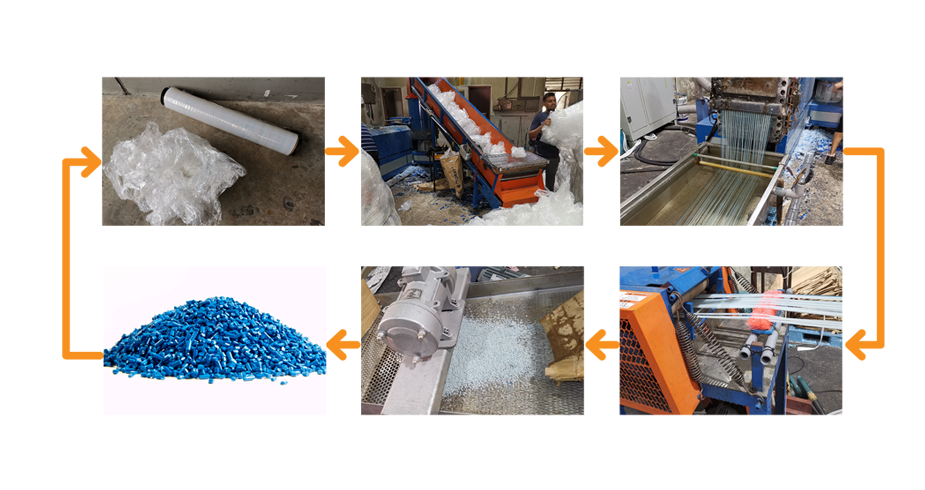

One such champion featured in our internal newsletter was Meng Leyin, a coordinator of our closed-loop plastics recycling programme with Plaslife. Since its inception in September 2019, the programme has enabled SATS to recycle 3,910 kg of our plastic waste materials into new plastic bags and trash bags which were purchased and reused in our production kitchens. Leyin made it her personal mission to ensure the programme’s success, going above and beyond her responsibilities to collect plastic samples from the kitchens and encourage colleagues and cleaners to sort the plastics for recycling.

Close-loop plastic recycling process.

Closed-loop recycling is a process in which post-consumer/commercial waste, such as plastic cling wrap is collected, recycled and used to make new products.

.png)

.png)